Injection Molding Equipment and Capabilities

- MODELING DESIGN

- MOLD FLOW ANALYSIS

- MOLDING FROM 85-2,200 TONS

- OVERMOLDING

- CUSTOM SECONDARY ASSEMBLY EQUIPMENT

- HEAT STAKING

- VIBRATION WELDING

- SONIC WELDING

- COMPLEX ASSEMBLIES

- PRODUCTION REWORKS

- SERVICE PARTS

- PROTOTYPE OR PRODUCTION VOLUMES

- PAINT

- TESTING AND DOCUMENTATION SUPPORT

Commodities

- DOOR PANELS

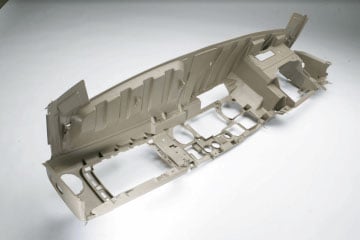

- INSTRUMENT PANELS

- CENTER CONSOLES

- OVERHEAD CONSOLES

- INTERIOR GARNISH

- FASCIAS

- BUMPERS

- GRILLS

Increase Product Development Efficiency with Low Volume Injection Molding

Over an extensive four plus decades of experience with injection molding we’ve developed a highly efficient operation facilitated by a skilled workforce and state-of-the-art equipment. Given our huge expertise and flexibility driven by varied types of equipment, we’re able to cater to a wide range of tooling and production demands. When it comes to plastic custom injection molding services too, we can meet your specific needs including a diverse mix of tools, even for low-volume molding, with our High Mix Low Volume (HMLV) offering.

We understand that our clients may have different production requirements from high to low at any given time. No matter what sector you belong to or what your volume or mix requirements, we’re committed to fulfilling all your requirements in-house, from the design to production tooling and manufacturing. Here is the number of ways you can enjoy the flexibility of low-volume injection molding:

1. High Variety - With our high mix, low volume you can opt for a high variety of products in small quantities.

2. Time Efficiencies - Low Volume production leads to faster production throughput, which can help save significant time.

3. Design Flexibility - Injection molding prototypes are faster to build with low volume injection molding, allowing you to make design changes faster and without incurring heavy expenses.

What Is Prototype Injection Molding?

Prototype injection molding is a type of low-volume injection molding that is used to quickly produce low volumes of parts for product testing and evaluation. A prototype is an early sample, model, or release of a final product.

Through the use of prototype injection mold tooling, our team of engineers can assess and validate the design, functionality, and manufacturability of your product during its development phase. Injection molding aluminum tooling created with CNC machining is ideal for small-volume injection molding because it heats and cools faster than steel molds. This reduces the standard lead time for small quantity injection molding so rapid prototyping is more efficient.

Why Is Low Volume Injection Molding Used?

Low-volume injection molding is used for a variety of reasons, including:

1. To produce low volumes of parts for product testing and evaluation

2. To speed up the production process

3. To create a prototype of a final product

Injection molding prototypes are faster to build with low-volume injection molding, allowing you to make design changes faster and without incurring heavy expenses.

What Are The 4 Stages Of Injection Molding?

Low-volume injection molding is a four-step process:

1. Clamping

2. Injection

3. Cooling

4. Ejection

Each step in the Low-Volume injection molding process is important in order to create high-quality parts. For automotive injection molding and Low-Volume injection molding, it is important to have a reliable and experienced partner who can help you through each step.

What Is The Process Of Low Volume Injection Molding?

First, the plastic is clamped and injected into a mold. Second, the molten plastic flows through the mold and fills all of the spaces inside. Once the plastic has cooled and solidified, the mold is opened and the part is ejected. Finally, excess material (flash) is trimmed from the part.

Why Is Injection Molding The Best Choice For Low Volume Plastic Parts?

Injection molding is the most common manufacturing process for low-volume plastic parts because it offers a number of advantages:

1. It is very precise and can produce high-quality parts.

2. It is economical for low quantities.

3. The parts are robust and can withstand high temperatures and pressures.

4. Flash can be easily trimmed from the parts.

What Is Insert Molding?

Insert molding refers to a specific procedure in turnkey injection molding that uses a pre-placed insert. This insert is an injection molding requirement and is commonly composed of metal or another material. It is incorporated into the mold prior to the injection of plastic. Insert molding is a technique that allows for the seamless integration of the insert and plastic components.

Subsequently, the molten plastic substance effectively encapsulates the insert as it solidifies and conforms to the mold's configuration. Through this method, the insert and plastic are seamlessly integrated into a unified component, consequently establishing a strong connection between them.

The procedure may involve the incorporation of different types of inserts, such as screws, pins, clips, or even more complex components. The resulting molded parts have added strength, conductivity, or functionality provided by the integrated insert.

What is Overmolding?

Overmolding or two-shot molding is a manufacturing procedure that encompasses the injection of multiple distinct materials into a singular mold. In the process of overmolding, a substrate, which can be either pre-molded or machined, is inserted into a mold.

Subsequently, a different material is injected into the mold, forming an encapsulated bond with the substrate. The primary objective of overmolding is to produce a unified component composed of multiple materials, each possessing distinct properties.

Overmolding enables the creation of intricate components using various materials in a single manufacturing cycle, thereby streamlining assembly and enhancing product dependability. Nevertheless, it is crucial to carefully assess material compatibility during the overmolding process, as successful bonding between the two materials is imperative.

Benefits of High Mix Low Volume Manufacturing

As the name suggests, high mix low volume manufacturing is the process wherein a high variety of goods can be produced in small quantities. If you need complex products with unique specifications, you can take advantage of our high mix, low volume plastic molding offerings. Our clients enjoy a high degree of customization and an increased variation of products with our HMLV services. Above all, they’re able to respond faster to changing consumer demands while simultaneously being able to reduce their inventory.

RCO Engineering - your partner from concept to production - can help with all your high mix, low volume injection modeling requirements. Advanced technology, proprietary processes, and of course our highly qualified and talented team helps us deliver extraordinary quality products.

Contact us to discuss your needs or if you have any questions!

We are a low-volume injection molding company with ISO 9001:2008 and AS9100C certification . We also carry numerous industry-specific quality and testing certifications.