MJF – Multi Jet Fusion

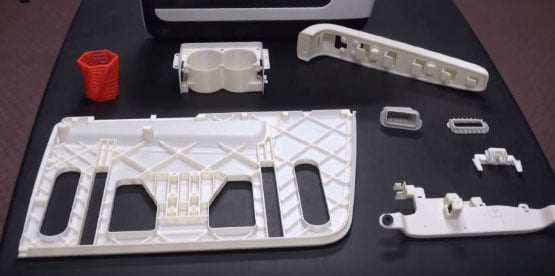

Finer detail and accuracy for intricate parts.

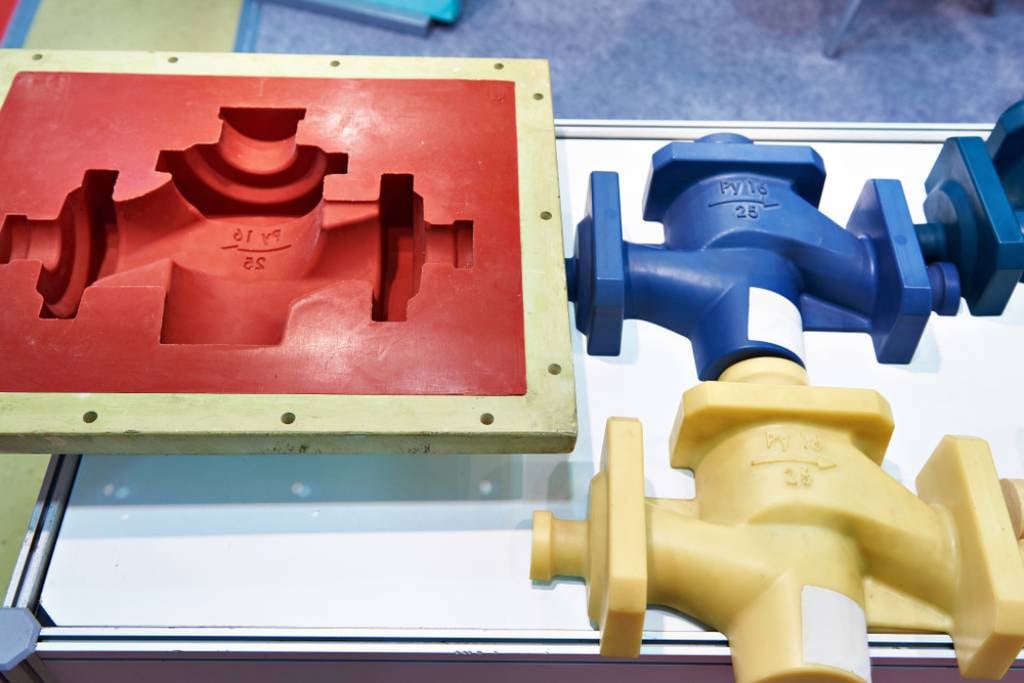

Produce functional parts. (E.G. ball bearing or hinged part )

Ability to print more parts in less time. (Low-Volume Production)

Parts are isotropic in all axes. Provides excellent chemical resistance to oils, greases, and alkalis. Achieves watertight properties without additional post-processing.

MJF technology is a cornerstone in additive manufacturing process, helping industries advance faster and more efficiently.