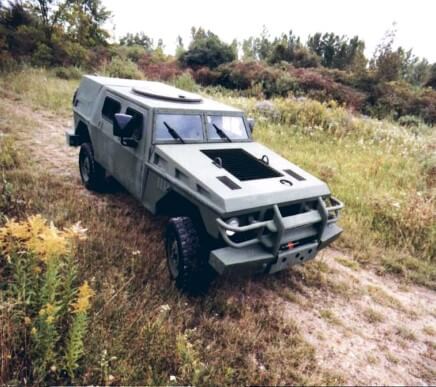

Your Partner for Lightweight and Prototype Military Vehicles.

Our track record and depth of expertise in automotive and aerospace engineering made us an attractive partner for the defense industry. Our partnership with the defense industry has included roles in product development for numerous interior, exterior, and chassis systems - utilized in the iconic Humvee to present day ground and aviation vehicles. We provide the defense industry with comprehensive design, engineering, manufacturing, and testing services.

Capabilities

TD

(Technology Demonstration)

- CONCEPTS TO MEET REQUIREMENTS (RFP)

- ENGINEERING MODELS & FEA (PROVEN STUDIES)

- FULL SCALE MODELS & HUMAN FACTORS

- OPERATIONAL PROTOTYPES

- WEIGHT-FOCUSED PROCESSES AND PRODUCTS

EMD

(Engineering and Manufacturing Development)

- MANUFACTURING DESIGN EXPERTISE

- COST REDUCING VAVE STUDIES

- DURABILITY TESTING

- ENVIRONMENTAL TESTING

- MODULAR ASSEMBLY, BUILD & MATERIAL ANALYSIS

- DEMONSTRATE SYSTEM INTEGRATION

LRIP

(Low Rate Initial Production)

- TOOLING ACCELERATED BUILDS: MOLDS & STAMPINGS

- PRODUCTION RELEASE DESIGN OPTIMIZATION

- SCALABLE PRODUCTION FOOTPRINT

- FINAL QC TESTING FOR EACH PART (ISO CERTIFIED)

- WHITE LIGHT SCANNING (3D MODEL CREATION)

- ITAR COMPLIANT

- COST AND WEIGHT MINIMIZATION

Strengthen Your Defense Supply Chain with RCO Engineering

RCO Engineering (ISO 9001:2015, AS9100D Certified | ITAR Registered) is a trusted partner for leading defense contractors and federal agencies. Our expertise in manufacturing and engineering supports mission-critical defense programs, helping you streamline your supply chain and meet the most demanding requirements.

Comprehensive Manufacturing Capabilities for Defense

We provide precision manufacturing solutions and partner with a network of vetted U.S.-based suppliers to meet your needs for quality and security, including:

- -ITAR-qualified facilities ensuring compliance with defense regulations.

- -Certifications such as ISO 9001:2015, AS9100D, and IATF 16949: 2016 for consistent quality.

- -Advanced traceability systems for material and process lot records.

Our capabilities include detailed inspection reports like CMM and First Article Inspection (FAI), ensuring every component meets strict defense specifications.

Technology Demonstrations in Defense

RCO Engineering supports technology demonstration projects that help defense agencies evaluate and refine new systems. Our rapid prototyping and precision manufacturing capabilities allow us to produce:

- -Prototype components for field testing and analysis.

- -Systems for experimental and proof-of-concept trials.

- -High-quality models for stakeholder evaluation.

We ensure that all parts are produced to the highest standards, enabling successful demonstrations and advancing the defense sector’s technological edge.

Engineering and Manufacturing Development (EMD)

The EMD phase is critical for refining and validating defense systems before full-scale production. RCO Engineering provides expertise in:

- -Iterative design and development support for system optimization.

- -Production of test articles that mirror final specifications.

- -Material and process traceability to ensure regulatory compliance.

By combining advanced engineering with robust manufacturing capabilities, we deliver components that align with the rigorous demands of the EMD phase.

Low-Rate Initial Production (LRIP)

As defense programs transition into LRIP, RCO Engineering is a reliable partner for producing limited volumes of high-precision parts. We provide:

- -Scalable manufacturing solutions tailored to meet LRIP schedules.

- -Strict quality controls to validate production processes before full-rate production.

- -Rapid adjustments to address design changes or improvements.

Our ability to deliver consistent quality ensures LRIP success and smooth transitions into full production.

Security and Compliance in Defense Manufacturing

We prioritize security and compliance to meet the stringent standards of the defense industry:

- -ITAR Compliance: Ensuring all defense-related projects adhere to International Traffic in Arms Regulations.

- -Data Security: All project files are encrypted at rest and in transit, protecting sensitive defense information.

Why Choose RCO Engineering for Defense Programs?

RCO Engineering is dedicated to supporting the defense sector with reliable, high-quality manufacturing and engineering services. From technology demonstrations to EMD and LRIP, our expertise helps you achieve program milestones while ensuring compliance, precision, and performance.

Ready to enhance your defense manufacturing capabilities? Partner with RCO Engineering for mission-critical solutions designed for the defense industry.

What Makes Manufacturing Services "Military Grade"?

RCO’s manufacturing services are considered to be "military grade" as they've undergone specific testing procedures and meet a high level of criteria. These extremely durable products are constructed to ensure they hold up better than standard materials in the industry. Military grade manufacturing services are higher quality and offer increased longevity.

RCO Engineering is an established leader in the industry and has earned the trust and respect of some of the top automotive companies in the world due to their focus on innovation. The company has the specialized expertise needed to fulfill the different requirements of their clients and is committed to continuous improvement.

When you're using the services of RCO Engineering, you can expect to receive top-quality products customized to your needs. Get the equipment and parts you need from a top defense manufacturing company.

As a reliable defense engineering and product development partner for the U.S. government and leading brands serving the defense industry, we not only deliver to stringent defense industry requirements, but to do it with the speed and quality we’ve built our reputation on. RCO is known industry-wide for our cutting-edge use of metals, composites, injection molding and more to reduce cost and weight for production assemblies.

ISO9001, ISO14001, ISO17025, NIST 800-171 Compliant, A2LA, SBA Certified, Design for Six Sigma, Cage Code:3K2U1, ITAR registered