You envision it. We’ll design, fabricate, build, and test.

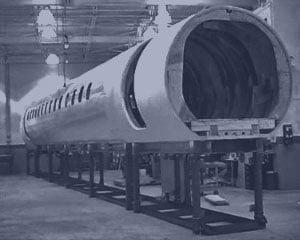

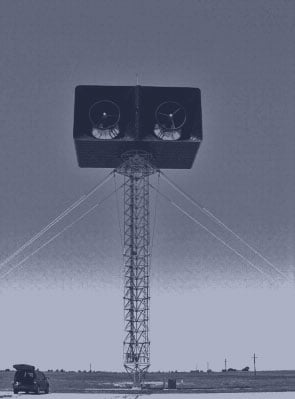

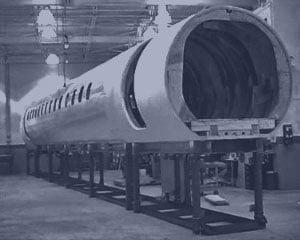

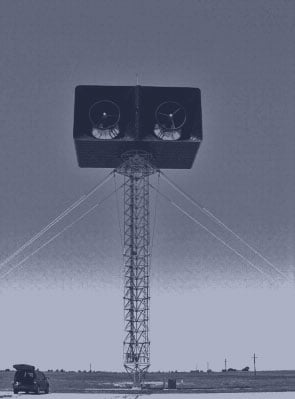

From small part modifications to seat frame assemblies, instrument panels, and muffler systems, to life-size vehicle and full-scale aircraft prototypes, our rapid prototyping services do it all. By orchestrating everything in-house, we have complete control of speed and quality. This flexibility makes us uniquely scalable and reliable.

Our rapid prototyping services are trusted by a wide range of companies that utilize prototypes– from startups to the world’s leading automotive, aerospace, and defense companies. Our vertical integration enables us to create virtually any rapid prototype in our own facilities on our own equipment by our talented staff.

Multi-material. Multi-scale.

We create rapid prototypes using:

- FDM ADDITIVE MANUFACTURING

- PLASTIC INJECTION MOLDS

- MOLDED OR MILLED FOAM

- COMPRESSION MOLDING

- METAL STAMPING AND FABRICATION

- MOLDED CARBON FIBER

- SILICON MOLDS

- VACUUM FORMING

- PATTERN DEVELOPMENT

- CUT & SEW

- WOOD, COMPOSITE, CAST AND BILLET ALUMINUM TOOLING

RCO was created on a realization that the automotive industry needed reliable and high-quality rapid prototyping services. For over 50 years we’ve worked with an unwavering commitment to deliver on that promise, coming out as one of the top rapid prototyping companies in the USA.

Our prototyping services are trusted by a wide-range of companies– from startups to the world’s leading automotive , aerospace and defense companies. Our vertical integration enables us to create virtually any prototype in our own facilities on our own equipment by our talented staff.

Multi-material. Multi-scale.

We create prototypes using:

- FDM ADDITIVE MANUFACTURING

- PLASTIC INJECTION MOLDS

- MOLDED OR MILLED FOAM

- COMPRESSION MOLDING

- METAL STAMPING AND FABRICATION

- MOLDED CARBON FIBER

- SILICON MOLDS

- VACUUM FORMING

- PATTERN DEVELOPMENT

- CUT & SEW

- WOOD, COMPOSITE, CAST AND BILLET ALUMINUM TOOLING

RCO was created on a realization that the automotive industry needed reliable and high quality prototyping services. For 43 years, we’ve worked with an unwavering commitment to deliver on that promise.

Benefits of Rapid Prototyping Services:

Working with a trusted prototyping partner gives you more than peace of mind -- it can help turn that idea into a real, tangible prototype that you can use to iterate, reference for manufacturing. Or, to get more done under the budget and time you have allotted. After all, if you can get to a production-ready design sooner, you'll be able to compress that timeline and get that new product out into the wild without straining your company's existing resources.

Benefit #1: It's Faster

As previously mentioned, the biggest benefit of rapid prototyping services is to enable you to take that idea and make it a reality by leveraging the skills and experience of a third-party engineering company. You've got the idea, but you probably don't have the proper technical skills and resources to bring it to fruition.

Instead of calling on employees that may not have much experience in working with certain materials or with meeting various real-world requirements, you can relay your design criteria to our rapid prototyping experts, and we’ll do the rest.

Benefit #2: More Affordable

Because you're not attempting to get up to speed on the fly, rapid prototyping services can also save money as well as time due to the vertical integration that we bring to the table. Whether your product requires working with plastics, metals, foams, composites, wood, or just about any other material, we know what it takes and we can help bring your product to life without blowing up your budget. If you have concerns about rapid prototyping materials and what goes best where, we can help you with that, too.

Benefit #3: Test Multiple Designs

If you're trying to conduct prototyping services in-house, you may only have the time or budget to try out one design -- and if it sinks, your project could be over before it even has a chance to start. But with a rapid prototyping services partner, the money you save will enable you to prototype and test a full range of designs before settling on that final version.

Spending the time upfront, can give you outsized savings when it comes to production, QA, and issues down the line.

Work With the Best Rapid Prototyping Companies Today

If you’re ready to get started with rapid prototyping, RCO Engineering can help. We have experience in engineering prototype services, automotive prototyping, and rapid prototyping in aerospace. We’ve positioned ourselves as one of the best companies that make prototypes on the market, and we look forward to learning about your prototyping and product development needs.