When it comes to plastic manufacturing processes, you might be wondering if you should choose compression molding vs injection molding. First, let’s look at each of the processes for compression molding vs injection molding.

What Is Compression Molding?

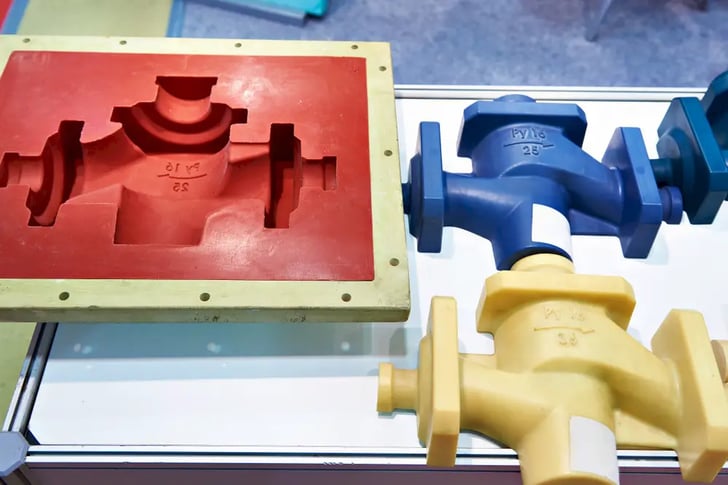

Compression molding involves using heat and pressure to create the finished part. The plastic material is placed into a mold and then heated to a specific temperature. With the heat applied, plugs are inserted to close the mold and add high pressure. The combined heat and pressure are what cause the material to conform to the shape of the mold cavity.

This process has a wide range of applications where the parts must be durable and strong with simple geometry. Some common applications of compression molding include:

- automotive parts such as dashboards, battery trays, and air ducts

- building and construction materials like roof tiles, electrical boxes, and paneling

- consumer goods such as toys, sporting goods, and household appliances

- electrical parts and electronics like electrical switches, control panels, and enclosures

Advantages of Compression Molding

When comparing compression molding vs injection molding, the process has lots of advantages. It is excellent for:

- producing large parts with a simple shape because the process can handle large volumes of material and high pressure

- producing cost-effective high-volume production runs

- producing stronger and durable parts as the high pressure and heat used in the molding process results in a strong, dense results

Disadvantages of Compression Molding

Of course, some drawbacks come with compression molding. It is not great for:

- producing parts with complicated shapes because the high pressure applied during the molding process can deform intricate features

- producing parts in a short time frame because the process is slower than injection molding

- producing parts without waste as excessive overflow must be removed before use

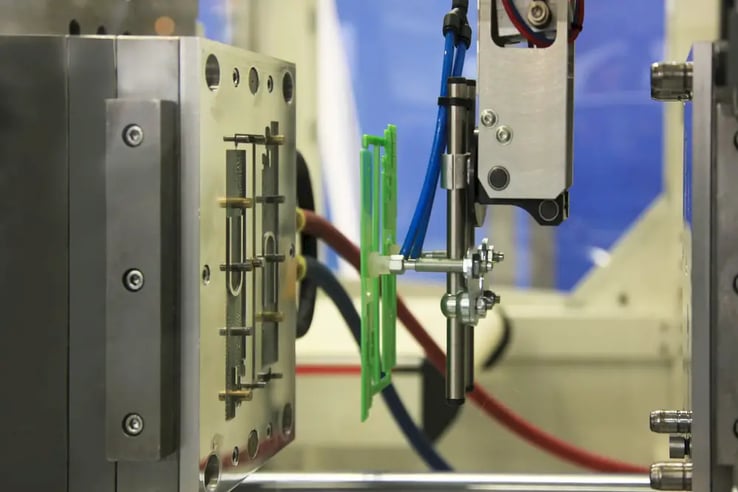

What Is Injection Molding

Injection molding also involves heat and pressure, but the process involves directly injecting the raw plastic into the mold. A screw pulls the plastic into a hopper and then heat is applied which melts the plastic. The molten plastic is then injected into the mold cavity and left to cool. Once the plastic is cooled, it solidifies into the shape of the mold.

This plastic manufacturing process is highly suitable for producing intricate, precise parts. Some common applications of injection molding include:

- automotive and mechanical parts like gears, door panels, and fuel system components.

- furniture like chairs and small tables

- consumer goods like toys, household appliances, musical instruments, and electronics components

- medical products like syringes and orthopedic implants

- packaging and containers like containers, lids, and bottle caps

Advantages of Injection Molding

Injection molding has lots of benefits for those who require precise, high-quality parts. It is perfect for:

- producing complex shapes and geometries with a high level of precision

- producing with shorter cycle times.

- producing multiple parts in each cycle to accommodate high volumes

- producing less waste and scrap during each cycle.

Disadvantages of Injection Molding

Injection molding isn’t without its faults. This process isn’t ideal because:

- it requires the creation of a custom mold

- It isn’t for creating extremely durable parts

- the initial lead times are long

- design changes can be costly

Compression Molding vs Injection Molding Cost

While each process has its pros and cons, they both have different applications and costs which must be factored into the manufacturing process.

Compression molding presents a cost-effective process for producing large, simple-shaped parts. This is what makes it suitable for high-volume production runs. The results are strong durable parts that are meant to last.

However, the process is limited in its ability to produce complex shapes and parts with high precision. Generally, the upfront costs for compression molding are cheaper.

Injection molding is the ideal choice for producing high volumes of complex parts that require high precision in craftsmanship. However, due to the nature of the manufacturing process, it requires a high initial investment. In the long run, this investment pays off for the precise work the process delivers. It is ideally suitable for producing with a high degree of accuracy and repeatability.

What Is the Difference Between Compression Molding and Injection Molding?

The main difference between compression molding vs injection molding is the way the raw plastic material is manipulated into the shape of the mold. Compression molding uses high pressure and heat, while injection molding uses a melted plastic material that is injected into the mold cavity.

Another difference between compression molding vs injection molding is the application with the former producing large durable parts and the latter producing more intricate ones. Whatever your needs are, we can provide either service for you.

Comments