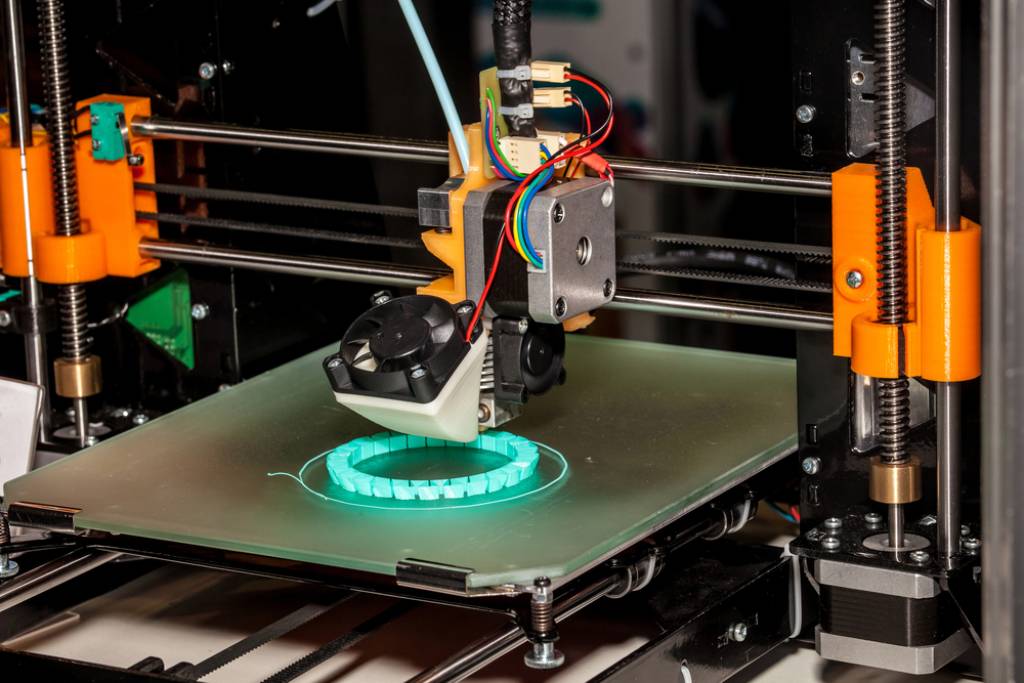

Product design has been enriched by 3D printing technology, offering many advantages and improvements. It has enabled designers to create complex products faster, with greater accuracy, and lower costs.

You might find that 3D-printed designs are also more durable. They can be used to create products that would have been impossible to make using traditional manufacturing techniques.

These are some ways 3D printing has enriched the product design process.

1. Rapid Prototyping

Rapid prototyping enables designers to quickly and affordably create functional prototypes. These prototypes can be used for testing and iterating a product before full production. This allows for rapid iteration of designs, faster time-to-market, and reduced costs associated with producing multiple prototype versions. The result is a more efficient design process and better end products.

This enables faster design iterations, allowing teams to identify and address issues early. Designers can test form, fit, and function more effectively, reducing the risks and costs associated with product development.

Designers can rapidly create and test product designs for form, fit, and function. This enables teams to identify issues early on. These tools also allow designers to iterate quickly, making changes that result in high-quality products that meet customer needs.

2. Better Customization and Design Freedom

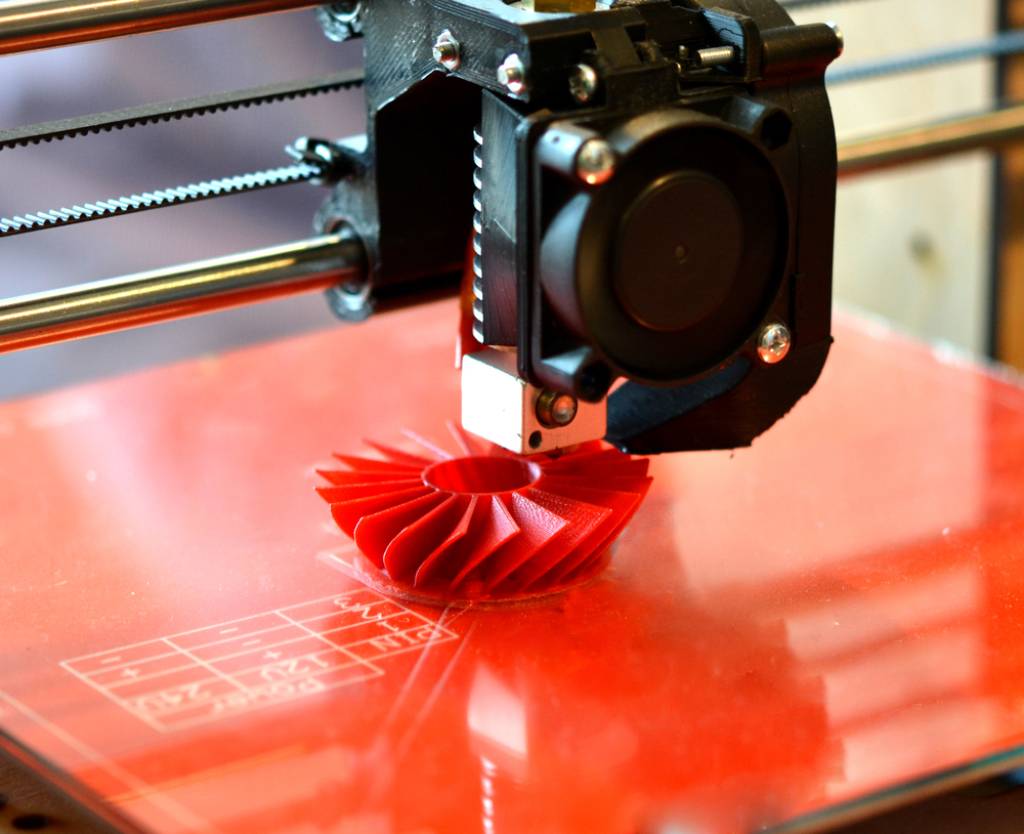

With the use of 3D printing in product design, designers have been given unprecedented creative freedom. A manufacturing process with 3D printing in product design allows designers to create complex geometries and intricate shapes.

The addition of 3D printing in product design has opened up a world of possibilities for designers and engineers alike. Successful product design starts with producing components that are tailored to the end-users’ specific needs or preferences. This can be done without significant increases in cost or production time.

3. Material Efficiency and Cost Effectiveness

Additive manufacturing or 3D printing in product design provides a more sustainable and economical way to produce complex objects. This manufacturing method builds objects layer by layer, significantly reducing material waste compared to traditional subtractive processes.

With 3D printing, material is added only where needed, reducing waste and promoting sustainability. This is especially important when using costly or scarce resources. This makes production processes more economical and eco-friendly.

By removing the need for expensive tooling, molds, and dies, 3D printing significantly reduces production costs. Designers have the leeway to explore and implement innovative designs quickly. This can lead to significant cost savings for manufacturers and help create a more sustainable future.

4. Integrated Components

Integrated components enable manufacturers and designers to produce parts in a single print. This can include:

- hinges

- gears

- electronic circuits

- other embedded components

This manufacturing process saves time and energy and costs much less than the traditional method. Instead of producing multiple parts separately and assembling them, 3D printed design are made in one print. Manufacturers can create products that are stronger, lighter, and more compact. Simultaneously, this reduces assembly time, labor costs, and possible errors.

5. Improve Team Collaboration

The manufacturing process can get tricky when working with large teams. You are working with a bevy of engineers, UX designers, and interaction designers just to get things right. Problem solving needs to have everyone on the same page.

With 3D printing, designers, engineers, and other stakeholders can easily exchange digital design files for a better workflow. A better workflow means not having to worry about compatibility issues or time-consuming file transfers. This makes it easier for teams to work together effectively throughout the design process. Better team communication leads to improved product designs with faster turnaround times.

6. Competitiveness with Shorter Time-to-Market

With a more streamlined process, 3D-printed designs drastically reduce the time it takes to bring a product from concept to market. This increased speed can give you a competitive edge by allowing you to get your products to market faster.

Product design processes are now streamlined for prototyping and production. The use of 3D printing enables businesses to rapidly get their products into the world. By leveraging the capabilities of 3D printing technology, businesses can open up new possibilities. These possibilities include offering customized products, short-run manufacturing, and on-demand production.

Take Advantage of 3D Printing for Your Product Design

The addition of 3D printing has wholly redefined product design. It allows for the cost-effective production of complex or customized parts with incredible speed and accuracy. All this is done by eliminating the need for tooling, molds, or dies. However, it would be best to have experts with experience in this technology to take advantage of it.

Comments