TL;DR: Metal stamping is a precise, high-speed process for shaping sheet metal. It supports various techniques and stamping types to produce reliable components efficiently.

Main points:

- Uses punch and die to shape metal parts

- Enables cutting, embossing, blanking, bending, and more

- Ideal for short and long runs

- Offers tight tolerances

- Supports progressive, transfer, four-slide, fine blanking, and deep draw stamping

- Suitable for high-volume, high-precision applications across metals like steel and aluminum

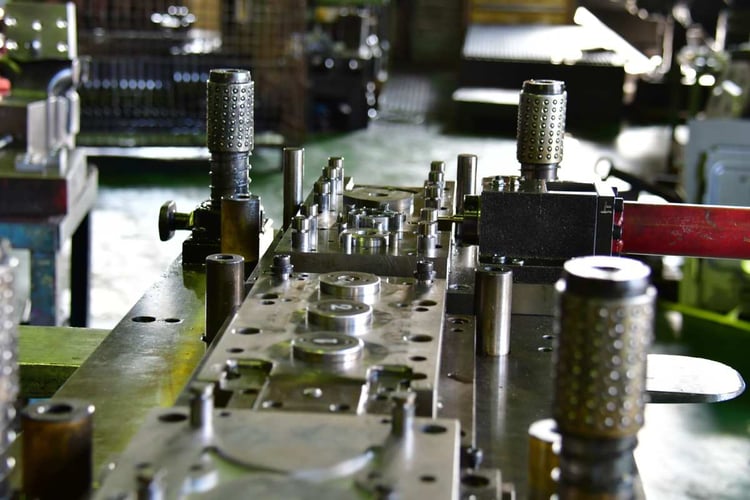

Metal stamping is a cold-forming industrial process. It uses precision dies and high-pressure presses to shape molded metal parts from sheet metal. The process uses a tool and die set to cut and form the metal.

The tool and die set consist of two parts:

- The Punch: This is a metal rod with the desired shape of the metal part.

- The Die: This is a metal block with a cavity that matches the shape of the punch. During this process, the stamping press is activated, and the metal sheet is placed between the punch and the die. Pressure pushes the punch into the metal sheet, forcing it into the die to form the desired shape.

What Makes Metal Stamping Effective?

Metal stamping machines are versatile machines that can do more than conduct simple metal stamping services. These machines can cut, stamp, punch, and shape the raw material. These machines use CNC programming to deliver precise metal components with every cycle.

Computer-aided design (CAD) programs and electrical discharge machining (EDM) help ensure accuracy. These factors make metal stamping ideal for short and long production runs.

Metal stamping projects can use aluminum, brass, copper, steel, or stainless steel. These metals offer strength, flexibility, or corrosion resistance depending on the application. Unlike machining or casting, metal stamping delivers faster cycle times, especially for large volumes.

It produces parts with tighter tolerances than most 3D printing methods. Use metal stamping when you need speed, consistency, and scalability. The metal stamping process can hold tolerances as tight as ±0.001 inches.

Automated inspections like vision systems, laser scanners, and CMMs ensure quality. Manufacturers use CNC metal stamping when precision and repeatability matter most.

Metal Stamping Techniques

Metal stamping is a low-cost high-speed manufacturing process. Which means it can produce metal components at a high volume. This makes stamping operations ideal for short and long production runs. These runs can also include other metal forming processes such as:

- Punching: This uses a die to cut the metal sheet into a specific form. This creates a hole in the material and removes the excess metal.

- Embossing: This can use a raw blank against a die. It could also pass the metal sheet over a roller die to create raised or recessed designs.

- Blanking: This uses a die to cut into a flat sheet of metal, leaving the desired shape of the component.

- Coining: This compresses a metal sheet between a die and or a punch or press. A punch tip repeatedly penetrates the metal to create the desired design.

- Bending: This involves the folding of a metal sheet to form the metal into the finished part. This is usually for V, L, or U-shaped components.

- Flanging: This uses a flare or flange on the metal workpiece through the use of a die or press. It may sometimes involve specialized flanging machines.

The Types of Metal Stamping Processes

Not all parts need the same metal stamping technique. Manufacturers choose different types of metal stamping processes depending on part complexity, volume, and required tolerances. Here are the four most common types:

Progressive Die Stamping

This metal stamping process uses a sequence of stamping stations where a metal coil is fed into a stamping press. This press contains stamping dies. The die moves with the press and as it goes down, the die closes the metal to form the part.

When the press releases the metal, it moves horizontally to the next station. This process works best for long, repeatable production runs. The die lasts through extended use without damage.

Transfer Die Stamping

This process is very similar to progressive die stamping. Instead, the metal part separates earlier and moves to another press, usually by conveyor. This metal stamping process is ideal for larger components.

Four-slide Stamping

This process may be called four-way stamping or multi-side stamping. It is best for creating complex parts that may have several twists and bends. It usually has four sliding tools to shape the metal workpiece instead of one vertical slide.

Two slides would strike the workpiece horizontally to give the desired shape. In some cases, it may have more than four moving sides. This type of metal stamping is versatile because it can accommodate different tool attachments to each slide. Overall, this makes it a perfect option if you want a low-cost production method that is incredibly fast.

Fine Blanking

Fine-blanking, or fine-edge blanking, has high accuracy and produces smooth edges. This type of metal stamping uses a mechanical press, hydraulic press, or a combination of both. Clamps hold the workpiece in place, then a blanking operation cuts the desired shape. The press then ejects the finished part.

This metal stamping process operates at a higher pressure than conventional metal stamping procedures. The edges of the component avoid fractures due to these conditions. Since it is a cold extrusion process, it is a one-step process that reduces the cost of fabrication.

Deep Draw Stamping

Deep draw stamping is a specialized metal stamping process used to form deep, hollow shapes from sheet metal. It works by drawing the metal into a die cavity using a punch and high pressure. This technique stretches the metal without cracking or wrinkling it.

Use this metal stamping technique when the part’s depth is greater than its diameter. It creates seamless, high-strength components without welding or assembly.

Excellence in Metal Stamping

Metal stamping produces large batches of parts quickly and accurately. Its usage ranges from the fabrication of simple brackets and clips to more complex auto parts and electronic components. Every project with us benefits from the exceptional knowledge and commitment of our metal stamping experts and craftsmen

Comments