Metal stamping is a versatile manufacturing process that involves shaping metal sheets into desired forms using dies and stamping machines. This method is commonly used in industries such as automotive and aerospace. Let’s explore this step-by-step metal stamping process guide.

1. Design and Concept

The product development process starts with conceptualizing the end product. This requires the design team and engineers to work together to create intricate designs based on specifications. Engineers use CAD (Computer-Aided Design) software to craft accurate models and drawings that fit dimensions, tolerances, and materials.

Material Selection

Selecting the appropriate material is essential for the success of the stamping process. Factors such as the material's strength, flexibility, and cost are considered. Common materials used in metal stamping include steel, aluminum, brass, and copper. The choice of material affects the tooling design and the stamping process itself.

Choosing a suitable material is crucial for the effectiveness of the metal stamping process. Factors like strength, flexibility, and cost are considered. Common materials used in metal stamping include:

- steel

- aluminum

- brass

- copper

The selection of material influences tooling design and impacts the overall stamping procedure. This step guarantees the finished product aligns with the desired requirements and specifications.

Following the requirements for the end part, the appropriate stamping press needed can be determined accordingly.

2. Creating the Tool and Die Set

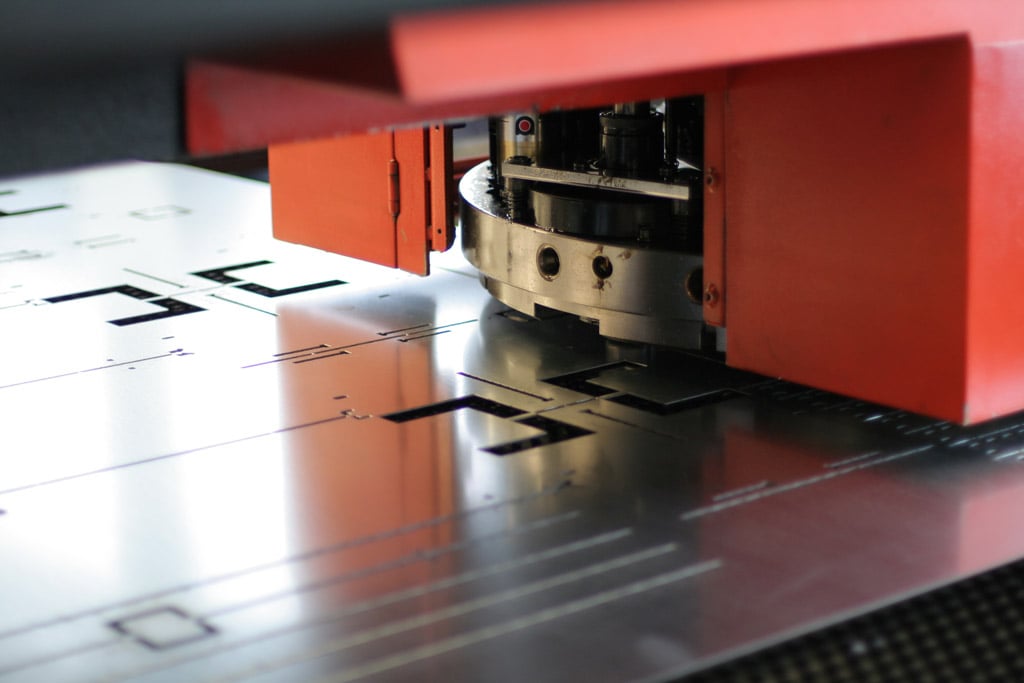

The next step in this metal stamping process guide is creating the tooling and die. Designing the die requires high-precision engineering. This ensures it can accurately produce the desired shape and withstand the forces exerted during stamping.

The tool and die set in a metal stamping press includes several critical components:

- Die: A die is a specialized steel tool used to shape and cut metal, featuring a cavity that mirrors the desired part shape.

- Punch: The punch moves downward to shape metal sheets in a press. It is usually attached to the press ram.

- Blank Holder or Stripper Plate: This secures the metal sheet and removes it from the punch as it moves back.

- Guide Pins and Bushings: The components ensure accurate punch and die alignment during press operation.

3. Developing a Prototype

Before full-scale production starts, a metal stamping prototype is created to test the die and stamping processes on a smaller scale to ensure the final product meets specifications. Based on prototype results, adjustments can be made to the design, material, or process. Modern stamping presses have advanced control systems for programming and monitoring the stamping process. Operators can optimize parameters like stroke length, speed, and pressure for materials and part geometries.

A typical stamping cycle involves the following steps:

- Clamping: The blank holder applies pressure to secure the metal sheet on the die.

- Stamping: The press ram exerts force to shape metal sheets in a die cavity. The force levels vary based on the material's properties.

- Ejection and Return: The metal part is ejected after stamping, and the punch returns for the next cycle.

Engineers use lubricants when stamping metal to reduce friction and wear on tools, enhancing part quality. Cooling systems can also disperse heat, particularly in fast or high-pressure stamping processes.

4. Mass Production

With everything set up, the metal stamping process can begin. The flat metal sheet often called the blank, is fed into the stamping press, where the die stamps the metal into the desired shape. Depending on the complexity of the design, the press can perform various actions, such as punching, bending, embossing, coining, and more.

5. Quality Control and Inspection

After the metal stamping process, a quality control team inspects each part to guarantee it adheres to the specified dimensions and tolerances. Quality control measures ensure high standards and consistency throughout the production run. These inspections can encompass visual assessments, dimensional measurements, and functional testing procedures to identify deviations and uphold quality standards.

6. Finishing Processes

The last part of this metal stamping process guide includes cleaning, heat treatment, plating, or painting. These processes are commonly done to improve appearance and protect against corrosion. If needed, the assembly of stamped parts with other components is often necessary to create the final product, involving methods such as welding, riveting, screwing, or adhesives for secure joining. These additional steps ensure the durability and functionality of the end product.

Produce Quality End Products

RCO Engineering offers comprehensive metal stamping services tailored to meet the needs of businesses of all sizes. Our dedicated quality department ensures every step of the metal stamping process is overseen with precision and care. We take pride in our high-quality products and customer satisfaction on every project.

Our range of services includes metal stamping production and low-volume sheet metal stamping, providing a complete metal stamping fabrication solution for your specific requirements.

Comments